|

"A life spent in making mistakes is not only more honourable but more useful than a life spent in doing nothing"

I heard someone say once that: "Guitar building is like hot dogs. They look and taste good but did you ever see how they make them?!"

Here is the square block that I am going to make the neck out of. It is approximately 25" X 3 1/2" X 2". As you can see I glued a little piece on the end where the head is to ensure that the slanted head will be long enough. I drew with a thin felt marker where I am going to make some rough cuts. You can't see it but I drew the same pattern on the other side of the board. It never hurts to plan a wee bit bigger to allow for any inaccuracies. At this point it is almost practical to insert the truss rod and glue on the fret board and then later shape the neck. I like to wait until I at least rough shape the neck. My reasoning for this is that when you cut up wood sometimes after it's cut, it bends or warps slightly to a certain extent. Did you ever buy a perfectly straight 2" X 4" at the lumber yard but when you take it home and ripped it down the middle, all of a sudden you have 2 warped bananas? Good mahogany is a very stable wood but I still watch out for things like that. After I rough shape the neck, I'm going to re check the surface where the fret board will go just to make sure it's still good and flat.

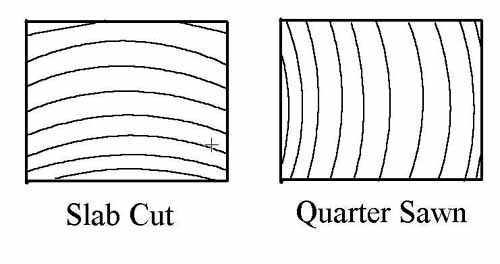

Now we have the making hot dogs part. Here is the very rough cut neck. It might encourage you to know that I have very little tools and so far this project has cost me nothing to make except for the truss rod that I made which cost about $2. The wood was from junk funiture and the exotic hard wood top of the body is from Peruvian floor boards. I didn't have the use of a band saw so I used a hand saw and a circular saw and hacked and cut away for about an hour to get the rough shape. (Kind of like doing brain surgery with a chain saw.) I say this so people won't think that they need the perfect set up, but of coarse good tools are a real help. A band saw would have made things a lot easier. I once sliced a piece of Bird's Eye Maple right down the middle with only a hand saw to make 2 book matched pieces for the top of an electric guitar. A little crazy and a lot of hard work but it worked. It's good to not be afraid leave everything a little big. You can always shape things down pretty easily later but you will be real sorry if you take too much off by accident. An important note: If you plan to put binding around the fret board it is a good idea to leave the neck stock a little wider then the fret board and then shave it down to size after the binding is on. Slab Cut or Quarter sawn Wood is cut either as a slab cut or a quarter sawn cut. Most common lumber is slab cut which means that the grain of the wood runs horizontal. A quarter sawn board has the grain general running vertically and will be stiffer. This is advantageous where you want more strength for the weight of the board. A great deal of the guitar necks are slab cut which is cheaper to make. Because of the fact that you are using a truss rod there is normally not a problem with it bending under the tension of the strings. A quarter sawn guitar neck will be stiffer. This gets to be controversial as people prefer one or the other which will effect how the guitar resonates. The neck is an important factor considering that around half of the length of the strings is stretched over the neck of the guitar and the other half, the Body. The wood I used for the neck happened to be quarter sawn Mahogany.

Here Is a childish drawing I made to illustrate a slab cut or a quarter sawn board. This is looking at the board end on or from the end grain. Note how the grain of the wood is angled in each example.

|